- Albanian

- Arabic

- Belarusian

- Bengali

- Czech

- English

- French

- German

- Hebrew

- Hungarian

- Indonesian

- irish

- Italian

- Japanese

- kazakh

- Persian

- Russian

- Thai

- Uzbek

- Vietnamese

Feb . 18, 2025 10:44

Back to list

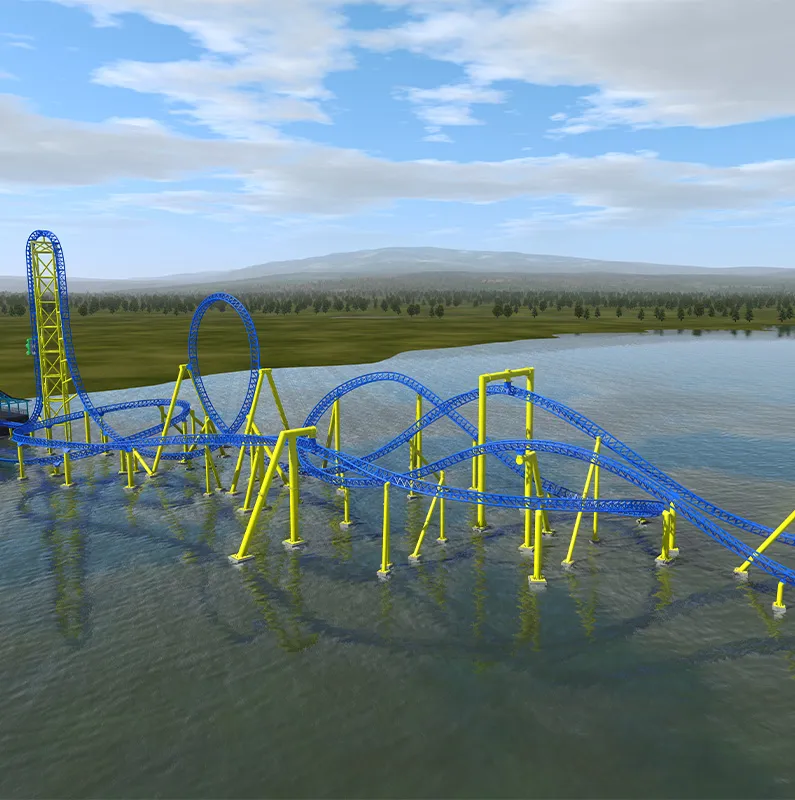

Family Roller Coaster

Designing and constructing a homemade roller coaster is an exhilarating endeavor that taps into the creativity and engineering prowess of any enthusiast. The journey from conception to the first exhilarating ride is filled with challenges, learning, and ultimately, satisfaction. This article delves into the intricacies of building a homemade roller coaster, providing insights garnered from real-world experiences and expert advice, while underscoring the importance of adhering to safety and quality standards.

Once construction begins, expertise in carpentry and welding becomes essential. This phase demands precision and adherence to the planned design. Experienced builders stress the importance of working incrementally, ensuring each section is securely fastened and aligned correctly before proceeding. This gradual approach not only facilitates error identification but also reinforces the build’s structural integrity. Testing is paramount after construction is complete. Initial tests should be conducted sans passengers, focusing on how well the coaster handles stress and whether its operational dynamics match projections. Sophisticated testing involves loading the coaster with weighted dummies to simulate the presence of actual riders. Continuous monitoring and tweaking during these tests help in pinpointing areas where adjustments are necessary. The role of documentation can't be understated. Cataloging each phase of the project serves multiple purposes it helps in troubleshooting, serves as a guide for future projects, and contributes to the body of knowledge available for fellow roller coaster enthusiasts. Moreover, these records augment credibility, offering a detailed account that underscores the technical competence and dedication invested in the project. Building a homemade roller coaster is not merely a hobby; it’s an intersection of engineering, creativity, and passion. It offers a profound sense of accomplishment and a unique experience for both the builder and the riders. By applying expert insights, maintaining rigorous safety protocols, and embracing a methodical approach to design and construction, you not only create an engaging ride but also establish yourself as a trusted authority in the fascinating world of homemade roller coasters.

Once construction begins, expertise in carpentry and welding becomes essential. This phase demands precision and adherence to the planned design. Experienced builders stress the importance of working incrementally, ensuring each section is securely fastened and aligned correctly before proceeding. This gradual approach not only facilitates error identification but also reinforces the build’s structural integrity. Testing is paramount after construction is complete. Initial tests should be conducted sans passengers, focusing on how well the coaster handles stress and whether its operational dynamics match projections. Sophisticated testing involves loading the coaster with weighted dummies to simulate the presence of actual riders. Continuous monitoring and tweaking during these tests help in pinpointing areas where adjustments are necessary. The role of documentation can't be understated. Cataloging each phase of the project serves multiple purposes it helps in troubleshooting, serves as a guide for future projects, and contributes to the body of knowledge available for fellow roller coaster enthusiasts. Moreover, these records augment credibility, offering a detailed account that underscores the technical competence and dedication invested in the project. Building a homemade roller coaster is not merely a hobby; it’s an intersection of engineering, creativity, and passion. It offers a profound sense of accomplishment and a unique experience for both the builder and the riders. By applying expert insights, maintaining rigorous safety protocols, and embracing a methodical approach to design and construction, you not only create an engaging ride but also establish yourself as a trusted authority in the fascinating world of homemade roller coasters.

Next:

Latest news

-

Flume Ride-Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.|Thrilling Water Attraction&Customizable DesignJul.30,2025

-

Flume Ride - Hebei Zhipao Amusement Equipment | Water Coaster, Thrilling DescentJul.30,2025

-

Flume Ride - Hebei Zhipao | Thrilling Water AttractionJul.30,2025

-

Flume Ride: Thrilling Water Attraction by Hebei Zhipao|Log Flume Manufacturers&Flume Ride DesignJul.30,2025

-

Flume Ride-Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.|Thrilling Water Coaster, Safe DesignJul.30,2025

-

Flume Ride-Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.|Thrilling Water Attraction, Safe DesignJul.30,2025