Premium Theme Park Equipment for Sale | Rides & Supplies

Navigating the Evolving Landscape of Amusement Equipment: Key Industry Trends

The global leisure and entertainment industry is undergoing a transformative period, driven by an insatiable demand for innovative and immersive experiences. This evolution profoundly impacts the market for theme park equipment for sale, pushing manufacturers to continuously innovate and adapt. A key trend is the shift towards integrating advanced technologies like virtual reality (VR), augmented reality (AR), and artificial intelligence (AI) into ride designs, creating multi-sensory adventures that captivate diverse audiences. This technological infusion enhances guest engagement and provides unique narrative experiences, moving beyond traditional thrill rides to encompass more story-driven attractions. Furthermore, there's a growing emphasis on sustainability and operational efficiency in new amusement park supplies. Operators are increasingly seeking equipment that not only offers high entertainment value but also minimizes environmental impact through reduced energy consumption, optimized waste management, and the use of eco-friendly materials. This holistic approach ensures long-term viability and aligns with global sustainability goals. The market is also seeing a surge in demand for highly specialized amusement park items, including media-based attractions, interactive dark rides, and record-breaking roller coasters that serve as flagship experiences. Simultaneously, the burgeoning family entertainment center (FEC) segment is driving demand for compact yet engaging indoor amusement equipment, catering to a broader demographic seeking localized leisure options. These trends collectively underscore a dynamic market where innovation, guest experience, and responsible operation are paramount.

Another significant trend shaping the procurement of amusement park items is the heightened focus on safety and operational excellence. Regulatory bodies globally are continuously updating safety standards, compelling manufacturers of theme park equipment to invest heavily in advanced safety features, robust structural engineering, and comprehensive testing protocols. This includes implementing redundant safety systems, real-time diagnostic tools, and predictive maintenance capabilities to minimize downtime and enhance guest security. The demand for customizable solutions is also on the rise, as park owners seek unique attractions that differentiate their offerings and align with specific themes or branding. This necessitates a close collaboration between park operators and manufacturers, moving beyond off-the-shelf products to bespoke designs that offer unparalleled guest experiences. The expansion into emerging markets, particularly in Asia and the Middle East, is fueling the growth of new theme park developments, creating substantial opportunities for suppliers of high-quality amusement equipment. These new parks often feature state-of-the-art attractions, incorporating the latest technological advancements and adhering to stringent international safety standards from inception. Concurrently, existing parks are investing in significant refurbishments and expansions to remain competitive, driving demand for both new installations and replacement components. This continuous cycle of innovation, safety enhancement, and market expansion defines the current landscape for sourcing reliable and cutting-edge theme park equipment.

The Art of Crafting Premier Theme Park Equipment: A Detailed Manufacturing Process

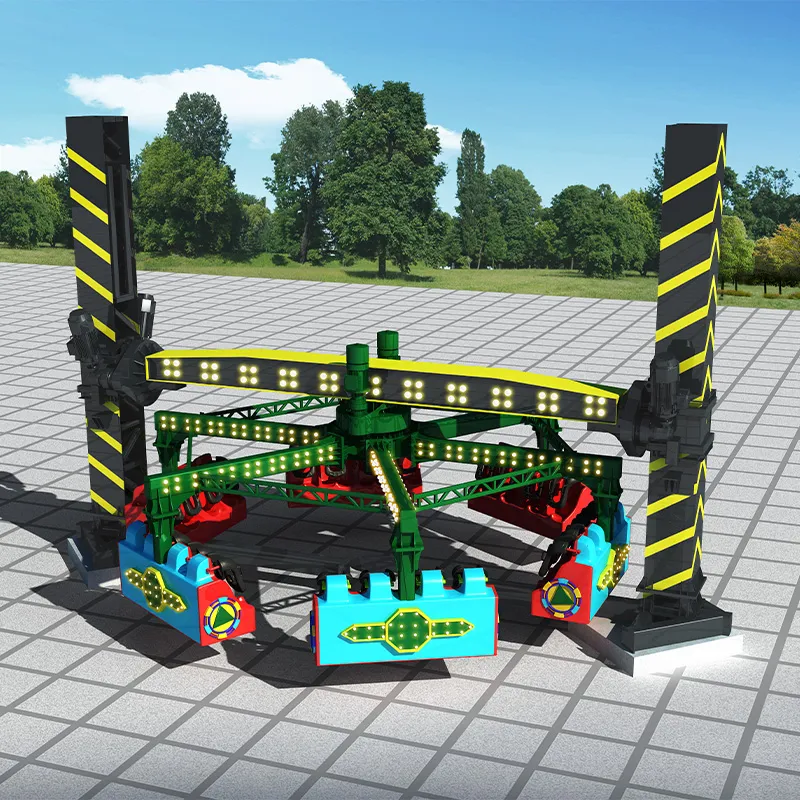

The production of state-of-the-art theme park equipment for sale, exemplified by complex attractions like "Time Gate," involves a meticulously engineered and highly controlled manufacturing process designed to ensure unparalleled safety, durability, and operational efficiency. The journey begins with advanced conceptual design, where structural engineers and creative designers collaborate to translate visionary concepts into detailed blueprints, leveraging sophisticated CAD/CAM software for precise modeling and simulation. Material selection is paramount, often involving high-strength steel alloys (e.g., ASTM A514, EN 10025 S355), aerospace-grade aluminum, and durable composite materials renowned for their fatigue resistance, anti-corrosion properties, and ability to withstand extreme environmental conditions and continuous stress cycles. Following design approval, raw materials undergo rigorous testing to verify their mechanical properties and chemical composition, ensuring they meet stringent international standards such as ISO and ASTM. Fabrication then commences with precision cutting technologies like CNC laser cutting and waterjet cutting, followed by expert welding using techniques such as Gas Metal Arc Welding (GMAW) or Submerged Arc Welding (SAW), performed by certified welders to achieve structural integrity and seamless joints. Each weld undergoes non-destructive testing (NDT) including ultrasonic testing and magnetic particle inspection to detect any internal flaws, a critical step in maintaining safety protocols for all types of amusement park items.

After primary fabrication, components proceed to advanced machining processes. Critical parts, especially those requiring high dimensional accuracy for smooth operation and minimal wear, are subjected to multi-axis CNC machining, ensuring tolerances are met within microns. Surface treatment is another vital stage, where parts are prepared and coated to enhance longevity and resistance against corrosion, wear, and UV radiation. This often involves processes such as galvanization, powder coating, or specialized marine-grade painting, chosen based on the equipment's intended operational environment. Assembly of the complex amusement park items is performed in controlled environments, integrating mechanical, electrical, hydraulic, and pneumatic systems. This stage also includes the installation of sophisticated control systems, often leveraging Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) for precise ride operation and diagnostic capabilities. Before final dispatch, every piece of theme park equipment for sale undergoes extensive quality control and rigorous testing. This includes dynamic load testing, static load testing, and functional testing to simulate real-world operational conditions, ensuring all safety interlocks, braking systems, and emergency procedures function flawlessly. Adherence to international safety standards like ASTM F2291 (Standard Practice for Design of Amusement Rides and Devices) and EN 13814 (Safety of Machinery - Amusement Rides and Devices) is strictly enforced, guaranteeing a projected service life exceeding 20-30 years with proper maintenance. This meticulous process ensures that the finished equipment delivers not only thrilling experiences but also unparalleled reliability and safety for operators in the entertainment, tourism, and urban leisure development sectors, offering advantages such as reduced energy consumption through optimized designs and superior corrosion resistance for lower maintenance costs.

Figure 1: Comprehensive Manufacturing Workflow for Advanced Amusement Equipment.

Technical Parameters and Performance Metrics for Advanced Amusement Rides

Understanding the critical technical parameters is essential when evaluating amusement park supplies and making informed procurement decisions for theme park equipment. These specifications define a ride's operational capabilities, safety margins, and return on investment. Key metrics typically include ride capacity, which dictates the hourly throughput of guests and directly impacts revenue potential, with modern attractions often designed to handle hundreds to thousands of guests per hour. Footprint requirements, encompassing the land area occupied by the ride and its queues, are crucial for site planning and maximizing park utilization, especially in urban or high-density locations. Power consumption figures, often expressed in kilowatts (kW), are vital for calculating operational costs and assessing energy efficiency, with advanced systems incorporating regenerative braking to reduce energy draw. Maximum speed and height requirements define the thrill factor and technical complexity, necessitating robust structural engineering and sophisticated control systems. Operational noise levels are increasingly important for parks located near residential areas, driving innovations in noise reduction technologies. Moreover, safety systems, including multiple redundant braking systems, ride vehicle integrity monitoring, and emergency stop protocols, are non-negotiable and meticulously engineered to exceed global safety standards like those set by ASTM and EN. These parameters provide a comprehensive overview of a ride's performance envelope, enabling park operators to select amusement park items that align with their operational goals, visitor demographics, and budgetary constraints.

Further technical considerations extend to the ride's material specifications, which are critical for longevity and maintenance. For instance, the type of steel used (e.g., high-tensile structural steel) for track and support structures, or the use of advanced composites for ride vehicles, directly influences the equipment's lifespan and resistance to environmental factors. Control system architecture, often featuring distributed PLC networks and Human-Machine Interface (HMI) displays, determines the ease of operation, diagnostics, and integration with park-wide management systems. Environmental resistance, including specifications for operating temperatures, humidity levels, and wind loads, ensures reliability across diverse climates. Furthermore, the Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR) are crucial reliability metrics that predict operational uptime and maintenance efficiency, directly impacting park profitability. Compliance with specific industry certifications, such as ISO 9001 for quality management and ASTM F24 for amusement rides, validates a manufacturer's commitment to excellence and safety. For theme park equipment for sale, these detailed parameters collectively form the bedrock of a successful investment, ensuring that the chosen attraction not only delivers thrilling guest experiences but also operates safely, efficiently, and cost-effectively over its extensive service life, providing a strong return on investment for the park operator.

Theme Park Equipment Key Performance Indicators (Typical Ranges)

Diverse Application Scenarios and Operational Advantages

The versatility of theme park equipment for sale allows for its strategic deployment across a wide spectrum of entertainment venues, each presenting unique operational advantages. Large-scale destination theme parks, for instance, are the primary beneficiaries, utilizing flagship attractions like high-thrill roller coasters or immersive dark rides, such as the "Time Gate" concept, to draw millions of visitors annually. In these environments, the operational advantages include high guest throughput, which directly translates into increased ticket sales and concession revenue, and the ability to create iconic experiences that drive repeat visitation and brand loyalty. The durability and low maintenance requirements of well-engineered amusement park items are crucial for minimizing downtime in these high-traffic settings, ensuring continuous operation and maximum profitability. Beyond traditional theme parks, family entertainment centers (FECs) and indoor amusement parks represent a growing market segment. For these venues, the focus often shifts to more compact, versatile, and high-engagement indoor amusement equipment and kiddie carnival rides for sale. The advantages here include efficient use of limited indoor space, year-round operation unaffected by weather conditions, and the ability to cater to a local community with diverse age groups. These smaller-scale installations often benefit from modular designs that allow for future expansion or reconfiguration, adapting to changing market demands.

Resorts and integrated leisure destinations also increasingly incorporate amusement park supplies as a core component of their guest offerings, enhancing the overall value proposition and extending guest stays. Here, attractions might be designed to complement existing themes, such as water park rides integrated into aquatic resorts or specialized interactive experiences within eco-tourism developments. The operational benefits revolve around enhancing guest satisfaction, providing unique selling points against competitors, and creating additional revenue streams beyond accommodation. Urban leisure developments, including shopping malls and mixed-use commercial complexes, are another emerging application. These projects leverage amusement park items to increase foot traffic, extend dwell times, and create vibrant community hubs. The advantage lies in generating a dynamic atmosphere that attracts diverse visitors, transforming retail spaces into entertainment destinations. Regardless of the specific application, the underlying principle remains the same: high-quality theme park equipment is a strategic asset that drives visitor engagement, optimizes operational efficiency, and significantly contributes to the economic success of leisure and entertainment ventures. The precise selection and thoughtful integration of these attractions are paramount to maximizing their inherent operational advantages across varied entertainment landscapes.

Technical Superiority and Innovation in Amusement Equipment

The competitive landscape for amusement park items for sale is continually shaped by advancements in technical superiority and innovation, differentiating leading manufacturers and driving the industry forward. A cornerstone of this superiority lies in advanced control systems. Modern rides are powered by sophisticated PLC (Programmable Logic Controller) networks, often augmented with SCADA (Supervisory Control and Data Acquisition) systems, which enable real-time monitoring of every critical parameter, from sensor feedback and motor performance to safety interlocks and emergency braking systems. This level of granular control ensures precise ride operation, enhances safety through immediate fault detection, and facilitates predictive maintenance strategies, significantly reducing unscheduled downtime and operational costs. Energy efficiency is another crucial area of innovation. Many contemporary theme park equipment designs incorporate regenerative braking systems that convert kinetic energy generated during deceleration back into usable electricity, substantially cutting power consumption and operational expenses. Furthermore, optimized motor and drive systems, coupled with lightweight composite materials for ride vehicles, contribute to a reduced energy footprint, aligning with global sustainability initiatives and offering significant long-term savings for park operators.

Enhanced safety features represent a continuous frontier of innovation within theme park equipment for sale. Beyond basic redundancies, advanced systems now integrate multiple layers of fail-safe mechanisms, including independent braking systems, comprehensive sensor arrays to detect anomalies, and sophisticated passenger restraint monitoring. The structural integrity of attractions benefits from finite element analysis (FEA) during design, allowing engineers to simulate stress points and optimize material usage, ensuring robust and long-lasting structures. Material science innovations also play a pivotal role, with the increasing use of advanced alloys and high-performance composites that offer superior strength-to-weight ratios, enhanced corrosion resistance, and extended operational lifespans compared to traditional materials. This translates into lower maintenance requirements and a reduced total cost of ownership for operators. The integration of immersive technologies like synchronized audio, video projection mapping, and haptic feedback systems transforms traditional rides into multi-sensory experiences, pushing the boundaries of guest engagement. These technical advancements collectively ensure that modern theme park equipment is not only thrilling and safe but also highly efficient, reliable, and capable of delivering unparalleled visitor experiences, ultimately translating into a strong return on investment for park owners.

Manufacturer Comparison and Selection Criteria for Amusement Equipment

Selecting the right manufacturer for theme park equipment for sale is a critical decision that impacts a project's success, safety, and long-term profitability. A thorough comparison should extend beyond initial cost to encompass a holistic evaluation of a manufacturer's capabilities, reputation, and support services. Key criteria for assessment include the manufacturer's R&D capabilities, which indicate their commitment to innovation and ability to develop cutting-edge attractions. Look for evidence of patented technologies, collaboration with academic institutions, and a track record of introducing novel ride concepts. Manufacturing standards and certifications are paramount; reputable manufacturers adhere to international benchmarks such as ISO 9001 (Quality Management), ASTM (American Society for Testing and Materials) F24 Committee standards, and European EN 13814 for amusement rides and devices. These certifications ensure rigorous quality control, adherence to safety protocols, and consistent product reliability. Another vital factor is the manufacturer's service and support infrastructure. This includes comprehensive pre-sales consultation, detailed project management during installation, thorough training for park staff, and robust after-sales support, encompassing spare parts availability and emergency maintenance services. A strong service network minimizes downtime and maximizes the operational lifespan of the amusement park items.

The manufacturer's track record and industry reputation are also critical indicators. Examining their portfolio of past projects, client testimonials, and industry awards can provide insights into their experience and reliability in delivering high-quality amusement park items for sale. Manufacturers with decades of experience, particularly those known for their work in amusement equipment ltd, often possess a deeper understanding of operational challenges and safety requirements. Customization options are increasingly important, as parks seek unique attractions that align with specific themes or space constraints. Evaluate a manufacturer's flexibility in adapting designs, integrating new technologies, and providing bespoke solutions that go beyond standard offerings. Furthermore, a manufacturer's global reach and logistical capabilities are important considerations for international projects, ensuring timely delivery and efficient installation regardless of geographical location. Finally, a transparent discussion about warranty periods, maintenance schedules, and long-term cost of ownership (TCO) will provide a clearer financial picture beyond the initial purchase price. By meticulously evaluating these criteria, park operators can forge partnerships with manufacturers who not only supply exceptional theme park equipment but also serve as reliable, long-term collaborators in their success.

Leading Amusement Equipment Manufacturers: A Comparative Overview (Illustrative)

Tailored Solutions and Bespoke Theme Park Equipment Design

In an increasingly competitive global market, the demand for custom theme park equipment for sale has surged, as park operators strive to create truly unique and unforgettable experiences that differentiate their offerings. Tailored solutions go beyond standard product catalogs, involving a deep collaborative process between the client and manufacturer to conceptualize, design, and realize attractions perfectly aligned with a park's specific theme, space constraints, and target demographic. This bespoke approach ensures that every element, from ride mechanics to thematic integration and guest flow, is optimized for maximum impact and operational efficiency. The process typically commences with an in-depth consultation, where the client’s vision, budget, and site limitations are thoroughly analyzed. This discovery phase is critical for defining the scope and parameters of the custom amusement park items. Following this, a conceptual design phase begins, translating ideas into preliminary sketches, 3D renderings, and detailed layouts, often incorporating advanced ride systems like those found in the "Time Gate" product. Engineering and R&D teams then refine these concepts, ensuring feasibility, safety compliance with global standards, and structural integrity. This iterative process allows for client feedback and adjustments, guaranteeing the final design meets or exceeds expectations.

Once the design is finalized and approved, the manufacturing phase commences, utilizing the precision fabrication techniques detailed earlier, often involving custom molds, specialized welding, and bespoke surface treatments to achieve the desired aesthetic and durability. For unique amusement park items for sale, this might include custom-fabricated structures, unique ride vehicles, or integration of complex media systems. Installation is another critical component of a tailored solution, with experienced technical teams managing on-site assembly, rigorous testing, and commissioning to ensure seamless integration into the park environment. Post-installation, comprehensive training programs are provided to park operations and maintenance staff, equipping them with the knowledge and skills necessary to operate and maintain the bespoke attraction safely and efficiently. The long-term support for custom theme park equipment also extends to ongoing maintenance, spare parts availability, and potential future upgrades, ensuring the attraction remains a top-tier asset for decades. This end-to-end customized approach not only delivers a unique guest experience but also provides significant strategic advantages, including enhanced brand identity, increased visitor loyalty, and a strong return on investment through a truly one-of-a-kind attraction.

Illustrative Application Cases and Client Success Stories

The successful deployment of high-quality theme park equipment for sale is best illustrated through tangible application cases that demonstrate significant operational and experiential benefits for clients. Consider a major regional theme park aiming to revitalize its appeal and attract a younger demographic. They invested in a custom-designed multi-launch roller coaster, a prime example of cutting-edge amusement park items, featuring advanced magnetic launch technology, multiple inversions, and an integrated media show. The manufacturer provided an end-to-end solution, from conceptual design to installation and operator training. Post-launch, the park reported a 25% increase in annual visitor numbers within the first year, a significant portion attributed directly to the new flagship attraction. Guest satisfaction scores related to thrill and innovation also saw a substantial rise, confirming the strategic value of the investment. This success story underscores how a well-executed investment in advanced theme park equipment can serve as a powerful draw, enhancing overall park profitability and market positioning.

Another compelling case involves a large family entertainment center (FEC) located within an urban retail complex that sought to maximize its limited footprint while offering diverse attractions. Their solution involved acquiring a suite of compact, high-throughput indoor amusement equipment, including a next-generation interactive dark ride and several innovative kiddie carnival rides for sale. The manufacturer's ability to customize layouts to fit the unconventional space and provide modular components was crucial. The operational advantage here was the FEC's ability to host a wider variety of events and cater to different age groups simultaneously, leading to increased repeat visits and higher average spend per guest. The equipment's high reliability and low maintenance requirements, typical of quality amusement park supplies, meant minimal operational disruptions, further contributing to profitability. Finally, a new eco-tourism resort in a developing region incorporated a unique, low-impact aerial adventure course and a themed water play area, both designed to blend seamlessly with the natural landscape. The chosen amusement park items prioritized sustainability, utilizing recycled materials and energy-efficient systems. This not only provided exceptional guest experiences but also enhanced the resort's commitment to environmental stewardship, attracting a niche market of environmentally conscious travelers and garnering positive media attention. These diverse application cases demonstrate the versatile impact of strategic investments in high-quality amusement equipment across various entertainment sectors.

Ensuring Trust: FAQs, Delivery, Warranty, and Support

Establishing trust is paramount when investing in substantial assets like theme park equipment for sale. Prospective buyers typically have a range of critical questions concerning safety, operational longevity, and post-purchase support. To address these, reputable manufacturers provide comprehensive information, often through detailed FAQs and clear contractual agreements. Common inquiries revolve around the equipment's safety certifications (e.g., adherence to ASTM, EN, and local regulatory standards), expected operational lifespan, and the frequency and scope of required maintenance. Manufacturers committed to trustworthiness will transparently detail their quality control processes, including material sourcing, fabrication inspections, and extensive pre-shipment testing. They will also provide insights into the typical delivery cycle, which can vary significantly based on the complexity and customization level of the amusement park items. For a standard ride, lead times might range from 6 to 18 months, encompassing design, manufacturing, logistics, and installation. Complex, bespoke attractions may require longer periods, sometimes exceeding two years. Comprehensive documentation regarding shipping logistics, customs clearance support, and on-site assembly schedules is crucial for seamless project execution.

A robust warranty commitment is a cornerstone of reliability for any amusement park equipment ltd supplier. This typically covers structural components for an extended period, often five to ten years, and mechanical/electrical components for one to three years, with clear terms on what is covered and under what conditions. Transparent warranty policies assure clients of the manufacturer's confidence in their product's durability and performance. Beyond the warranty, proactive customer support is vital for the long-term success of any theme park equipment installation. This includes readily available spare parts, often managed through an online portal or dedicated customer service line, minimizing downtime during unforeseen repairs. Technical support should be accessible for troubleshooting and operational guidance, possibly including remote diagnostics and on-site assistance when necessary. Comprehensive training programs for park operators and maintenance teams are also a standard offering, ensuring staff are fully proficient in safe operation, routine checks, and minor repairs. This holistic approach to support, from pre-purchase transparency to robust post-installation services, underscores a manufacturer's commitment to partnership and ensures maximum operational uptime and profitability for the client's amusement park items for sale.

Scholarly References

- International Association of Amusement Parks and Attractions (IAAPA) Annual Reports on Industry Trends and Statistics.

- Journal of Leisure Research – Articles on Consumer Behavior and Experience Design in Amusement Parks.

- ASTM International F24 Committee Standards for Amusement Rides and Devices.

- European Committee for Standardization (CEN) EN 13814: Safety of machinery - Amusement rides and devices.

- Themed Entertainment Association (TEA)/AECOM Theme Index and Museum Index Reports.

- Academic papers on Structural Engineering and Materials Science in Large-Scale Structures.

-

Flume Ride-Hebei Zhipao|Thrilling Water Coaster&Amusement EquipmentAug.18,2025

-

Bolter With High Torque And Low Noise - Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.Aug.18,2025

-

Bolter With High Torque And Low Noise - Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.Aug.18,2025

-

Bolter With High Torque And Low Noise - Hebei Zhipao | High Torque, Low NoiseAug.18,2025

-

Quality Used Amusement Park Equipment for SaleAug.18,2025