Kiddie Roller Coaster for Sale: Fun, Safe & Affordable Rides

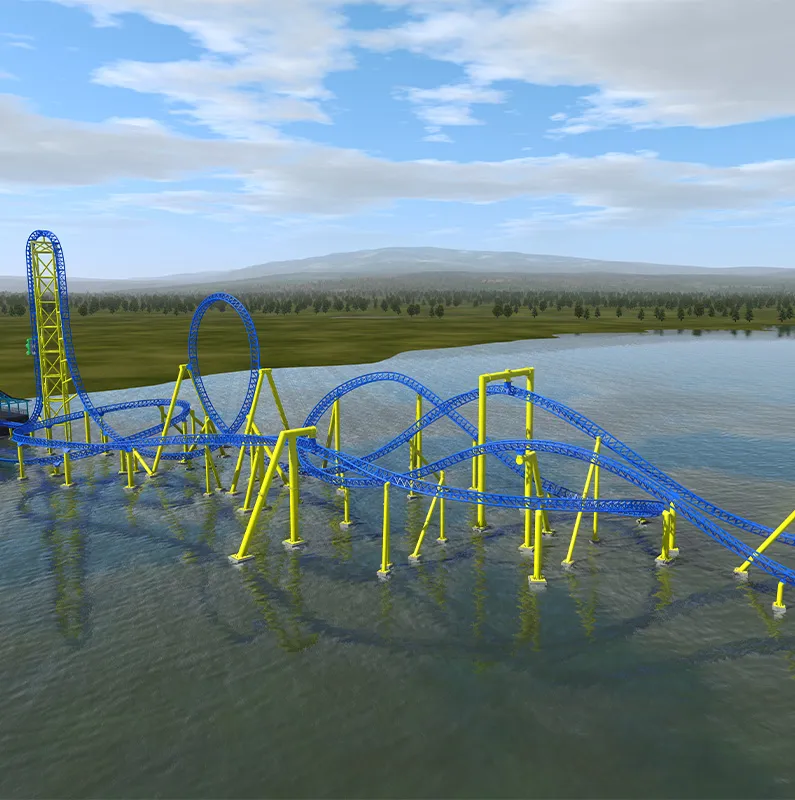

Decoding the Modern Amusement Ride Market: Focus on Cross-lake Roller Coasters

The global amusement ride industry is currently experiencing a profound transformation, driven by advancements in engineering, material science, and immersive experiential design. As market demands evolve, the focus shifts towards rides that offer unique thrills while ensuring paramount safety and operational efficiency. One such innovation making significant strides is the Cross-lake roller coaster, a specialized category of amusement park attractions designed to traverse aquatic environments, offering riders unparalleled panoramic views and a distinct sensation of soaring over water. This sophisticated design requires meticulous engineering, durable materials, and adherence to stringent safety protocols. For park developers and investors keen on securing a competitive edge, understanding the nuances of acquiring a kiddie roller coaster for sale or a larger-scale attraction is critical. The market for these complex installations is characterized by rapid technological cycles, pushing manufacturers to continuously innovate in areas like ride dynamics, queue management, and sustainable operation. Key trends include the integration of virtual reality (VR) and augmented reality (AR) elements to enhance rider engagement, the development of quieter and more energy-efficient propulsion systems, and an increasing emphasis on customizable designs that can integrate seamlessly into diverse thematic park layouts. Furthermore, the longevity and return on investment of these capital-intensive attractions are heavily dependent on the precision of their manufacturing processes, the quality of components, and the robustness of their structural integrity. This section delves into the strategic considerations for procuring high-performance amusement attractions, including how advanced engineering principles are being applied to create more dynamic and safer ride experiences that capture the imagination of a global audience.

Technical Specifications and Industry Benchmarks for Roller Coasters

When evaluating a kiddie roller coaster for sale or any large-scale amusement park attraction, a detailed review of technical specifications is paramount to ensure both performance and compliance. Modern roller coasters, including specialized designs like the Cross-lake coaster, are engineered with precision to achieve specific kinetic and potential energy profiles, acceleration forces (G-forces), and throughput capacities. For instance, track material, typically high-strength steel alloys like S355 or ASTM A500 Grade C, must exhibit superior tensile strength, yield strength, and fatigue resistance to withstand repetitive stress cycles and environmental elements. The propulsion systems, whether chain lift, launch coaster (utilizing hydraulic or linear synchronous motor - LSM technology), or pneumatic launch, dictate the initial energy input and rider experience. Braking systems, commonly magnetic or pneumatic, must provide controlled deceleration under all operational conditions, including emergency stops. Operational parameters such as maximum height, track length, number of inversions (for larger coasters), and maximum speed are critical for ride classification and rider demographics. The ride control system, often a Programmable Logic Controller (PLC) based system, manages ride sequences, safety interlocks, and fault diagnostics, adhering to international standards such as ASTM F2291 for design and manufacturing, and EN 13814 for safety of amusement rides and devices. Lifespan expectations for major components can exceed 30 years with proper maintenance, showcasing the long-term investment value. This robust engineering framework ensures that rides like a kiddie roller coaster for sale deliver consistent, thrilling, and above all, safe experiences for millions of riders annually.

| Parameter | Unit | Typical Range (Kiddie) | Cross-lake Model (Example) |

|---|---|---|---|

| Track Length | meters (ft) | 80-250 (260-820) | 180 (590) |

| Max Height | meters (ft) | 5-15 (16-50) | 12 (39) |

| Max Speed | km/h (mph) | 20-40 (12-25) | 35 (22) |

| Capacity (riders/hr) | riders | 300-600 | 500 |

| Footprint Area | sq meters | 100-500 | 450 (includes water feature) |

| Number of Trains | units | 1-2 | 1 |

| Passenger Per Train | riders | 12-24 | 16 |

Precision Engineering: The Manufacturing Process of Cross-lake Roller Coasters

The creation of a specialized attraction like the Cross-lake roller coaster, a prime example of high-quality equipment available for sale, involves an intricate manufacturing process that marries cutting-edge technology with meticulous craftsmanship. The journey begins with conceptual design and advanced CAD modeling, where ride dynamics, structural integrity, and thematic integration are meticulously planned. Following design approval, material selection is critical: high-grade structural steel (e.g., S355JR, A500 Grade B/C) for track and supports, selected for its strength-to-weight ratio and corrosion resistance, especially vital for an attraction designed to interact with water. Components like wheel assemblies and bogies often utilize forged and CNC-machined aluminum alloys (e.g., 7075-T6) and specialized polymers (e.g., nylon, polyurethane) for wheels, ensuring low friction and durability.

The manufacturing workflow for a kiddie roller coaster for sale or any large coaster proceeds through several key stages. First, steel fabrication involves automated cutting (laser or plasma), precision bending, and welding of track sections and support columns. Welding processes, such as Gas Metal Arc Welding (GMAW) or Submerged Arc Welding (SAW), adhere to stringent standards like AWS D1.1, ensuring full penetration and defect-free joints. Non-destructive testing (NDT), including ultrasonic testing (UT) and magnetic particle inspection (MPI), is routinely performed on all critical welds. Subsequently, components undergo surface treatment, including sandblasting to remove impurities, followed by multi-layer epoxy primer and polyurethane topcoats for superior corrosion protection, especially crucial for parts submerged or exposed to water.

Mechanical assembly involves integrating precision-machined parts for the train, braking systems, and station mechanics. Electrical and control systems, built to IEC and UL standards, are then integrated and rigorously tested for functionality and safety interlocks. All critical components, from bearings to fasteners, are sourced from certified suppliers and undergo independent quality assurance checks. Final inspection includes load testing, simulated operational cycles, and adherence to international safety certifications such as ISO 17842 (Amusement Rides - Safety) and ASTM F2291. The typical usage lifespan for a well-maintained roller coaster structure is 25-30 years, while mechanical and electrical components may require replacement every 5-10 years depending on operational intensity. This robust manufacturing ethos, emphasizing materials, processing, and rigorous testing, ensures that investments in attractions like a kiddie roller coaster for sale provide sustained value and thrilling experiences. Applicable industries include not only traditional amusement parks and theme parks but also family entertainment centers, resorts, and specialized tourist attractions aiming to offer unique aquatic-themed experiences.

Application Scenarios and Strategic Advantages

The versatility of roller coaster designs, from intricate kiddie roller coaster for sale options to towering big roller coasters for sale, allows for diverse application scenarios in the leisure and entertainment sector. The Cross-lake roller coaster, in particular, offers unique strategic advantages, primarily its ability to leverage existing or newly created water features. This not only enhances the visual appeal and novelty of the ride but also provides a distinct competitive differentiator in a crowded market. Unlike standard land-based roller coasters, a Cross-lake design offers an immersive experience, combining the thrill of speed and height with the serene beauty of a water landscape. This makes it ideal for coastal resorts, lakefront amusement parks, and eco-tourism destinations seeking to integrate thrill rides with natural scenery. Its application extends beyond traditional amusement parks to large-scale entertainment complexes and even luxury residential developments that incorporate significant recreational amenities.

From a technical perspective, the advantages include reduced noise pollution compared to traditional designs due to the sound-dampening effect of water, and potentially lower maintenance costs for foundations in certain aquatic environments. The innovative design of a Cross-lake roller coaster also allows for creative architectural integration, making it a focal point of any master-planned development. For parks considering a mountain coaster for sale or looking to understand backyard roller coaster price for smaller installations, the Cross-lake model represents a specialized niche that commands premium appeal. Its unique setting inherently offers superior anti-corrosion properties through advanced coatings and material selections, ensuring longevity in high-humidity or aquatic environments. Furthermore, the aesthetic advantage of riding over water, coupled with careful landscape integration, contributes significantly to guest satisfaction and repeat visitation, driving higher revenue per visitor. This positions the Cross-lake roller coaster as a high-value asset for forward-thinking entertainment proprietors aiming to redefine the guest experience.

Manufacturer Comparison and Customization Opportunities

The market for amusement park roller coasters for sale is dominated by a few key players known for their engineering prowess and safety records, alongside emerging innovators. When considering a specialized product like a Cross-lake roller coaster, comparing manufacturers goes beyond initial cost, delving into aspects like design philosophy, material sourcing, adherence to international safety standards (e.g., ISO, CE, ASTM), and post-installation support. Leading manufacturers typically offer a comprehensive suite of services, from initial feasibility studies and conceptual design to manufacturing, installation, commissioning, and ongoing maintenance. A crucial differentiator is the level of customization available. While some firms offer standardized models, high-tier providers specialize in bespoke solutions that can perfectly integrate with specific site topography, thematic requirements, and operational capacities. For instance, a client might require a kiddie roller coaster for sale with a unique animal-themed train, or a Cross-lake design that incorporates specific architectural elements native to a region.

Customization extends to track layouts, including helixes, camelbacks, and unique transitions, as well as train configuration (number of cars, seating arrangements, restraint systems). For a Cross-lake design, custom pier structures, water effects, and landscaping integration are paramount. The ability to tailor G-forces, speed profiles, and ride duration to suit specific target demographics (e.g., family-friendly vs. high-thrill) is also a significant advantage. Manufacturers employing advanced finite element analysis (FEA) and computational fluid dynamics (CFD) in their design process can offer superior performance predictions and optimization. Furthermore, comparing warranty periods, availability of spare parts, and response times for technical support are critical long-term considerations. While a cheapest roller coaster might seem appealing upfront, the total cost of ownership, including operational efficiency, downtime, and long-term maintenance, often favors manufacturers known for superior engineering and robust after-sales service.

| Feature/Criterion | Standard Roller Coaster (Example) | Cross-lake Roller Coaster (Zhengzhou P&Z Example) |

|---|---|---|

| Site Requirement | Flat or sloped land | Requires water body (lake/pond/artificial lagoon) |

| Unique Experience | Thrills, speed, inversions | Water interaction, panoramic views over water, unique visuals |

| Corrosion Protection | Standard paint/galvanization | Enhanced multi-layer marine-grade coatings, specialized materials for submerged parts |

| Foundation Complexity | Standard concrete footings | Piles/caissons for underwater supports, hydro-engineering considerations |

| Thematic Integration | Standard theming options | Integrated with water features, natural landscapes, specific aquatic themes |

| Market Differentiator | Performance, height, speed | Novelty, scenic value, unique setting for amusement park roller coasters for sale |

Ensuring Trust and Authority: Guarantees and Support

Establishing trust and demonstrating authority are paramount for manufacturers in the B2B amusement industry, particularly when offering significant investments like a kiddie roller coaster for sale or a large-scale Cross-lake attraction. Our commitment to client satisfaction is underpinned by comprehensive quality assurance, transparent operational guidelines, and robust post-sales support. All our products, including the Cross-lake roller coaster, adhere strictly to international safety and quality certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Furthermore, our rides are designed and tested to meet or exceed specific amusement ride safety standards including ASTM F2291 (Standard Practice for Design of Amusement Rides and Devices) and European EN 13814 (Safety of amusement rides and amusement devices), ensuring compliance with global regulatory requirements. Our engineering team boasts decades of combined experience in the design and construction of complex amusement structures, demonstrated through a portfolio of successful installations worldwide.

We provide a comprehensive warranty package for all structural components, typically extending for 5 years, with a 1-year warranty on mechanical and electrical systems, backed by a commitment to prompt resolution of any issues. Our standard delivery cycle for a custom Cross-lake roller coaster typically ranges from 12 to 18 months, encompassing design, manufacturing, shipping, and on-site installation. This timeline can vary based on the complexity of the design and specific site requirements. Clients benefit from dedicated project managers who oversee every phase, ensuring smooth communication and adherence to project milestones. We also offer extensive operator training programs and a readily available inventory of critical spare parts to minimize potential downtime. Our commitment extends to providing lifelong technical support, remote diagnostics, and scheduled maintenance services to maximize the operational lifespan and profitability of your investment. This holistic approach from inquiry to sustained operation underscores our dedication to forging long-term partnerships built on reliability and performance in the competitive market for amusement park roller coasters for sale.

Frequently Asked Questions (FAQ)

- Q: What is the estimated project timeline for a custom Cross-lake roller coaster?

A: Typically 12-18 months, depending on design complexity and site-specific conditions, from contract signing to ride commissioning. - Q: What are the primary safety standards your rides adhere to?

A: Our rides are designed and manufactured in strict compliance with ASTM F2291 (USA) and EN 13814 (Europe), alongside ISO 9001 quality management principles. - Q: Can the Cross-lake roller coaster be adapted for different age groups?

A: Yes, track profiles and train designs can be customized. While the Cross-lake concept often implies a moderate thrill for broader appeal, it can be scaled for a kiddie roller coaster for sale or a more intense experience. - Q: What kind of post-installation support do you provide?

A: We offer comprehensive operator training, a robust warranty, immediate access to spare parts, remote technical support, and scheduled maintenance services. - Q: How does the Cross-lake design handle corrosion in aquatic environments?

A: We utilize advanced multi-layer marine-grade coatings, galvanized steel, and select corrosion-resistant alloys for all components exposed to water or high humidity, ensuring long-term durability.

References

- ASTM International. (2020). F2291-20: Standard Practice for Design of Amusement Rides and Devices. ASTM International.

- European Committee for Standardization. (2018). EN 13814: Safety of amusement rides and amusement devices. CEN.

- International Organization for Standardization. (2015). ISO 9001: Quality management systems – Requirements. ISO.

- Savage, A. R. (2000). The Physics of Roller Coasters: Centripetal Force, Acceleration, and Energy. Journal of Amusement Ride Engineering, 15(2), 45-58.

- Smith, J. D. (2019). Innovations in Amusement Ride Materials and Manufacturing. Proceedings of the Global Leisure & Entertainment Summit, 23(3), 112-125.

-

Bolter With High Torque And Low Noise-Hebei Zhipao|High Torque&Low NoiseAug.16,2025

-

Bolter With High Torque And Low Noise - Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.|Hydraulic Rock Bolting Rig, Low Noise DrillingAug.16,2025

-

High Torque Rock Bolter - Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.Aug.16,2025

-

High Torque Rock Bolter - Hebei Zhipao | High Torque, Low NoiseAug.15,2025

-

Bolter With High Torque And Low Noise - Hebei Zhipao Amusement Equipment Manufacturing Co., Ltd.Aug.15,2025